Micro CE/Ipqc/Fqc/QA Auto Spare Service Motor Wholesale Hot Sale CNC Machining Parts

Description

Basic Info.

| Application | Metal forging Machinery |

| Inspection | IQC, Ipqc,Fqc,QA |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Certificate | CE, TUV, SGS or as Your Requirement to Do Test by |

| Service | Warm and Quick Response Service Provided by The Pr |

| Delivery Time | 10-15 Days for Sample, 35-40 Days for Bulk Order |

| CNC Milling Work Range | 510mm*1020mm*500mm |

| CNC Turning Work Range | φ0.5mm-φ150mm*300mm |

| Machining | CNC |

| Product Packaging | Wooden Cases, Pallets, Cartons, PVC Pallets, PP Ba |

| Heat Treatment | Annealing, Normalizing , Nitriding, Tempering , C |

| Technology | Precision Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metal, S |

| Processing Degree | Micro Machining |

| Processing Type | Broaching, Drilling,Grinding ,Turning ,Milling ,T |

| Transport Package | Carton + Euro Pallets |

| Specification | 1200x800 |

| Trademark | Ramo-Lixin |

| Origin | China |

| HS Code | 7326901900 |

| Production Capacity | 50000PCS/Month |

Product Description

Factory Outlet OEM Grinding Carbon Steel Stainless Brass Drilling Turning Machining PartsCustomized Description| Product name | CNC machined partsTurning and milling parts |

| Service Type | OEM & ODM Service |

| Processing type | Broaching, DRILLING,Grinding ,Turning ,Milling ,Tapping Thread |

| Material Capabilities | Aluminum, brass, bronze, copper, hardened metal, stainless steel, steel alloy |

| Processing degree | Micro Machining |

| Product packaging | Wooden cases, pallets, cartons, PVC pallets, PP bags, and according to customer requirements |

| Machining | CNC |

| Technology | Precision Machining |

| Heat treatment | Annealing, Normalizing , Nitriding, Tempering , Carbonitriding |

| Dimensions | Customized |

| Packaging Details | Carton + pallet or Plywood cases or Other package as per customer requirement |

| Material | Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. |

| Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |

| Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |

| Copper: C11000,C12000,C12000, C36000 etc. | |

| Plastic: ABS, PC, PE, POM, Delrin, Nylon,PP, Peek etc. | |

| Other: Titanium,etc.We handle many other type of materials. Please contact us if your required material is not listed above. | |

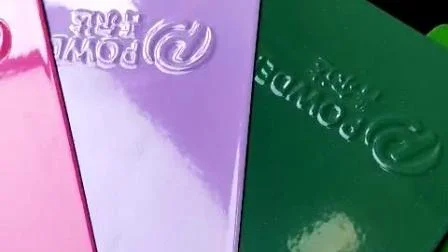

| Surface Treatment | Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black,Electrophoresis black |

| Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. | |

| Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing. | |

| Brass: Nickel plating,chrome plating,Electrophoresis black,Oxide black,Powder coated. | |

| Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. | |

| Anodizing, Sandblasting, Metal Plating, Polishing, Painting, Powder coating, Brushing ,Silk-screen , Laser Engraving etc. | |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/.step/.cad/.gis/.x_t |

| Testing Machine | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, projecter machine, roughness tester, hardness tester and so on |

| Certificate | CE, TUV, SGS or as your requirement to do test by the third party |

| Delivery time | 10-15 days for sample,35-40 days for bulk order |

| Packing | Plywood pallet, plywood box or as per your requirement |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Service | Warm and quick response service provided by the professionalExport Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

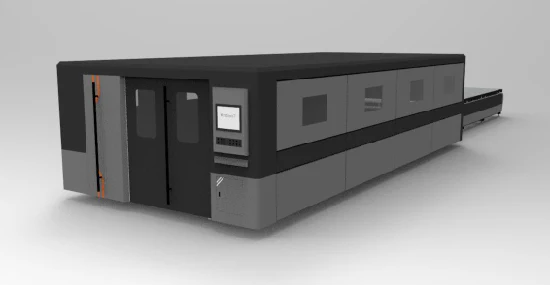

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm | |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

Ramo-Lixin was established in 2005,with many years experience in machining industry.We're specialized in CNC machining/ milling/turning, laser cutting and stamping.We own our factories, several production line to meet your different needs and requirements.Beside, we have set up an expert quality control department to precheck&recheck all the prod-ucts before shipping.Our objective is to develop and produce products to meet your exact specifications, in themeanwhile, offer reasonable prices and professional services to satisfy your expectations andbudget.

Ramo Lixin(Ningbo)Co, Ltd. ltd has high precision 3 axis, 4 axis and 5 axis cnc vertical mill-ing center which import from Taiwan and Japan, precision grinding machines, cnc lathe ma-chines, wire cut, EDM and cnc laser engraving machine about 20 units. our skilled machinists canmake turned and milled parts using a wide range of plastic and metal materials.

1.Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in zhejiang, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4. Is it possible to customize the logo?

Yes,We can support silk printing, pad printing, laser engraving, etching, cnc machining engraving.

5.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

6. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

7. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

8.Is the sample available? free?

Samples are available and some are free.m CNC Machining Anodized Aluminum DIY Mechanical Keyboard Case

9. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

10. What surface treatment services do you have?

Customer's Demand,Anodized ,Plating,PVD ,Nickel Plating,Sandblasting,Powder Cating,Polishing,Multi-color anodized,Painting etc.

11. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Prev: Turning Processing, Milling Processing, Non

Next: Chemical Product Silicone Waterproofing Agent Strong Insoluble Water

Our Contact