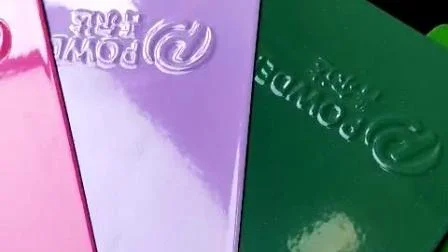

Industrial Pure Polyester Powder Coating for Metal Finish

BRIEF INTRODUCTION Electrostatic polyester powder coating gives an excellently homogenous surface. Due to a high level o

Description

Basic Info.

| Level | Finish Coat |

| Certification | RoHS, ISO9001 |

| Substrate | Steel |

| Expiration Date | 1 year |

| Formation Mechanism | Conversion Type |

| Packaging | Carton |

| Transport Package | Carton, Pallet |

| Specification | 20kg/carton |

| Trademark | Purda |

| Origin | Jiangsu, China |

| Production Capacity | 200tons/Month |

Product Description

BRIEF INTRODUCTIONElectrostatic polyester powder coating gives an excellently homogenous surface. Due to a high level of production control, areas of thicker paint at the edges and corners or the 'orange peel' texture usually associated with powder coating are minimized. Electrostatic polyester powder coating is a more cost effective option than PVDF coatings but not as durable. Baked at low temperatures, it is an energy efficient coating technology suitable for interior and exterior applications. Large panels, curves and complex forms can be easily coated. UV stable and highly weather resistant, its performance can be tailored to meet the demands of particular applications and various degrees of gloss can be specified.

RANGE

High Gloss, Gloss, Semi Gloss & Matt

Fine Texture & Ripple

Antique Finishes and Tinted Lacquers

Metallic Effects

Sparkle Effects

Fluorescent Effects

ADVANTAGES

High solid content, excellent fullness of film

Thick coating is available

High sanding performance & good abrasion

High application efficiency & easy to apply

Primer can improve hardness of top coat & save the consumption of topcoat

SPECIFICATION

| Main Material | Polyester resin,barium sulfate,titanium dioxide |

| Surface Type | Gloss,matte,wrinkle,sandgrain,antique,Hammer,crocodile skin,wood effect,candy,chrome,transparent,semitransparent,metallic,and special pattern |

| Powder Properties | Specific gravity : 1.3 - 1.75 (depend on colors) |

| Average particle size : 35 - 45um | |

| Coating Properties | Film thickness(ISO 2178) :60 - 90 μm |

| Coverage:15m2 based on 60μm | |

| Pencil hardness: ASTM D3363,H-2H | |

| Adhesion :GB/T 9286-1998,0 grade | |

| Bending test:GB/T 6742 ,=<2mm | |

| Cupping test:GB/T 9753,>=7mm | |

| Direct and reverse impact (ASTM D2794) : > 50kg.cm | |

| Salt spray Resistance ( ASTM B117, 1000hrs)(Maximum undercutting ,1 mm ): No blistering or loss of adhesion | |

| Heat and moisture test GB/T 1740,>=1000 hours,no change | |

| Application Schedule | Applied by : Electrostatic spraying devices |

| Curing schedule :10 minutes at 200 ºC | |

| Advantage | Good adhesion,anti-corrosion,UV resistant, strong coating film, |

| Accurate colors, good leveling | |

| Shelf Life | 12 months |

STORAGE CONDITIONS

Temperature: ≤30ºC Humidity Conditions: Dry, Cool and Ventilated Storing Requirement: Cannot be piled up over 4 cartons; Seal the PE bag after using; Away from VOC, fire and heat; Validity: 6 months (If the parameters are tested to be qualified, the product still can be used expire date)

CERTIFICATE

PACKAGE AND DELIVERY

FACTORY

QC

APPLICATION

FAQ:

1.Factory or trading company?

We are Factory. We specialize in powder coating industry over 15 years, welcome friends from worldwide to visit our factory.

2.M.O.Q :

The minimum order is 500kg ,each color ≥ 100kg

3.Colors:

RAL color :we usually use RAL colors that is widely used in paint industry and easily find in market

Custom color : Color matching is available , if you have colors panel ,please send to us for matching .

4.Prices:

Prices depend on the colors and using environment ,for prices please tell us the colors and using environment (indoor use or outdoor use).

5.Time of delivery :

Production will take about 5-8 days after receipt of prepayment, it depends on the quantity.

6.Payment :

30% T/T prepayment , 70% T/T before shipment (or against BL) or LC at sight .

7.Samples:

1kg powder sample is available for each color for your testing.Sample is free of cost,but we will highly appreciate if you pay for the courier charge.

Our Contact

Send now