Glass Optics Plasma Surface Treatment/Plasma Cleaning

Description

Basic Info.

| Model NO. | MD-D5 |

| Trademark | MINDER |

| Origin | Guangzhou-Guangdong |

| Production Capacity | 1000sets/Month |

Product Description

Product description

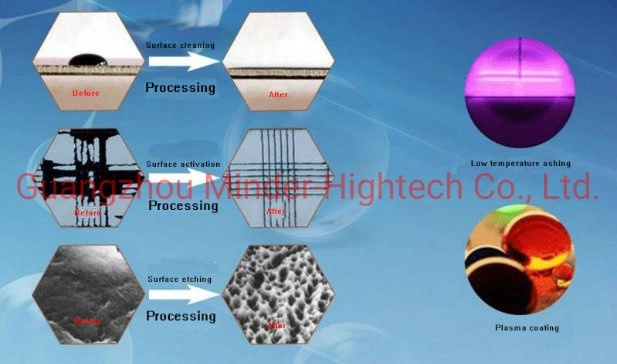

(1.1)The role of plasma cleaning

The principle of plasma cleaning is mainly:

(A)Etching on the surface of materials - physical effects

A large number of active particles in the plasma, such as a large number of ions, excited molecules, and free radicals, act on the surface of the solid sample, which not only removes the original contaminants and impurities, but also produces an etching effect to roughen the surface of the sample. Many fine pits are formed, increasing the surface ratio of the sample. Improve the wetting properties of solid surfaces.

(B)Activation bond energy, cross-linking

The energy of the particles in the plasma is between 0-20 eV, and most of the bonds in the polymer are between 0-10 eV.

When a solid surface is used, the original chemical bond on the solid surface can be broken, and the free radicals in the plasma and these bonds

The formation of a network of crosslinked structures greatly activates surface activity.

(C)Forming new functional groups - chemistry

If a reactive gas is introduced into the discharge gas, a complicated chemical reaction occurs on the surface of the activated material, and new functional groups such as a hydrocarbon group, an amino group, a carboxyl group, and the like are introduced, and these functional groups are all active groups, which can significantly improve the surface activity of the material.

Product principle:

1. Principle of structural composition: The structure of atmospheric low-temperature plasma cleaning machine is divided into three parts: high-voltage excitation power supply, plasma generator spray gun, and intelligent control system.

1.1 High-voltage excitation power supply: Plasma generation requires high-voltage excitation. Atmospheric low-temperature plasma is excited by medium-frequency power supply. The frequency is 10-40KHz, and the high voltage is 10KV. The parameters can be adjusted according to the actual conditions of the product, with excellent and stable treatment effect.

1.2 Plasma generator spray gun: atmospheric low-temperature plasma generator spray gun, can be divided into two types of jet direct injection and rotary direct injection, the difference is that the processing area is different, and can be combined with automated production line solutions according to customer needs.

1.3 Intelligent Control System: The function of the control system is to control the operation of the entire atmospheric low-temperature plasma cleaning equipment, power regulation, and various protections of the overall system.

Technical Parameters

Item No# | AP-WH+D5/50/80 | AP-BE+D5/50/80 | AP-BK+D5/50/80 |

Processing Width | 5mm / 50mm / 80mm | 5mm / 50mm / 80mm | 5mm / 50mm / 80mm |

Input Voltage | AC220V/50Hz | AC220V/50Hz | AC220V/50Hz |

| 220V | 220V | 220V | |

Power Output | 500W for 5mm | 500W for 5mm | 500W for 5mm |

| Frequency | 20-50Khz | 20-50Khz | 20-50Khz |

Air Pressure | 4kg/0.4MPa | 4kg/0.4MPa | 4kg/0.4MPa |

Gas Used | Air / N2 | Air / N2 | Air / N2 |

Cable Length | 2m | 2m | 2m |

Internal control mode | Digital control | Digital control | Digital control |

External control mode | Analog control, on-off remote control | Analog control, on-off remote control | Analog control, on-off remote control |

| (mm)L×W×H | 300*400*200mm | 240*390*280mm | 140*370*420mm |

| Weight | : 10.8kg | : 13.5kg | : 11.3kg |

| 4mm+3m: 0.8kg | 4mm+3m: 0.8kg | 4mm+3m: 0.8kg | |

| 50mm+3m: 4.2kg | 50mm+3m: 4.2kg | 50mm+3m: 4.2kg | |

| 80mm+3m: 4.2kg | 80mm+3m: 4.2kg | 80mm+3m: 4.2kg |

Performance advantage

1.German circuit technology:

High-density plasma is generated by imported high-voltage excitation power circuit technology to ensure superior cleaning results

2.Unique discharge technology:

Special treatment and special structure of the discharge device to ensure a stable and uniform plasma

3.With assembly line production:

According to the needs of the user on site, configure the optimal production line to greatly improve production efficiency.

4.Low temperature cleaning:

According to the temperature requirements of different occasions, it does not affect the temperature of the cleaning products.

5.Quality product parts:

All parts of the product are made of imported top quality parts to ensure superior equipment performance.

6.Precision CNC machining: imported precision CNC machine tool processing technology, and equipped with imported three-coordinate measuring instrument for quality monitoring

7.Comprehensive security protection:

Temperature safety protection function, overload protection function, air pressure abnormality protection function, short circuit breaking alarm protection function, various misoperation protection functions

Application industry:

Wide range of cleaning and activation applications, professionally used in mobile phone screens, PE, PP, PVC, PET, ceramics, glass, lithium batteries, rubber, polymer materials, etc.

Optional automation solution

Gantry:

Scope of application: It can be directly connected to the original production line, the length of the line is 300 ~ 600mm, and the requirements on the line are relatively high. Can be customized multi-head plasma cleaning machine.

XYZ axis platform:

Scope of application: suitable for products with small processing area, no need to be connected to the production line, the products can be directly processed after being placed, and a certain production capacity can be achieved.

Can be customized multi-head plasma cleaning machine.

Automated assembly line:

Scope of application: It is suitable for products with large processing area, seamlessly connects to the original assembly line, automates the whole process, does not increase labor costs, does not reduce the original production capacity, through product optimization, increases production capacity, greatly improves the yield and reduces production costs.Can be customized multi-head plasma cleaning machine.

Our factory:

If you are interest in this product,please feel free to contact me,thanks:

Prev: Inorganic Surface Treatment with Zirconia and Alumina Titanium Dioxide/TiO2 for General Usage

Next: Customized Plastic Mold Tooling Mould Plastic Spare Parts Plastic Injection Moulds

Our Contact