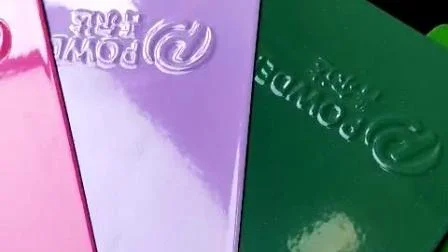

Fast Curing Pure Epoxy Powder Coating with Excellent Insulation Properties

IntroductionThis product is one kind of thermoset pure epoxy powder coating based on epoxy polyester and epoxy curing ag

Description

Basic Info.

| Model NO. | E-RD4962-S7 |

| Method | Spray |

| Level | Primer |

| Certification | ISO14001, ISO9001 |

| Substrate | Steel |

| Components | Film Forming Matter |

| Paint Film Property | Insulating Varnish |

| Formation Mechanism | Non Conversion Type |

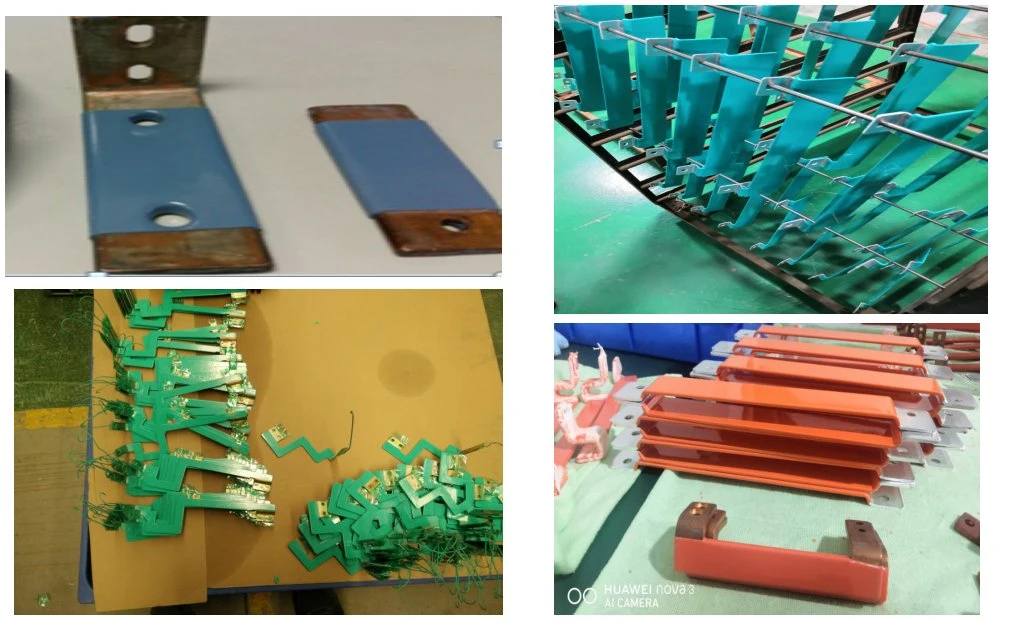

| Application | Busbar, Electric Motor Stator, Rotor, etc. |

| Basic Property | Electric Insulation |

| Transport Package | 20kg/Box |

| Trademark | KINTE |

| Origin | China |

| HS Code | 3907999000 |

| Production Capacity | 500 Tons Per Month |

Product Description

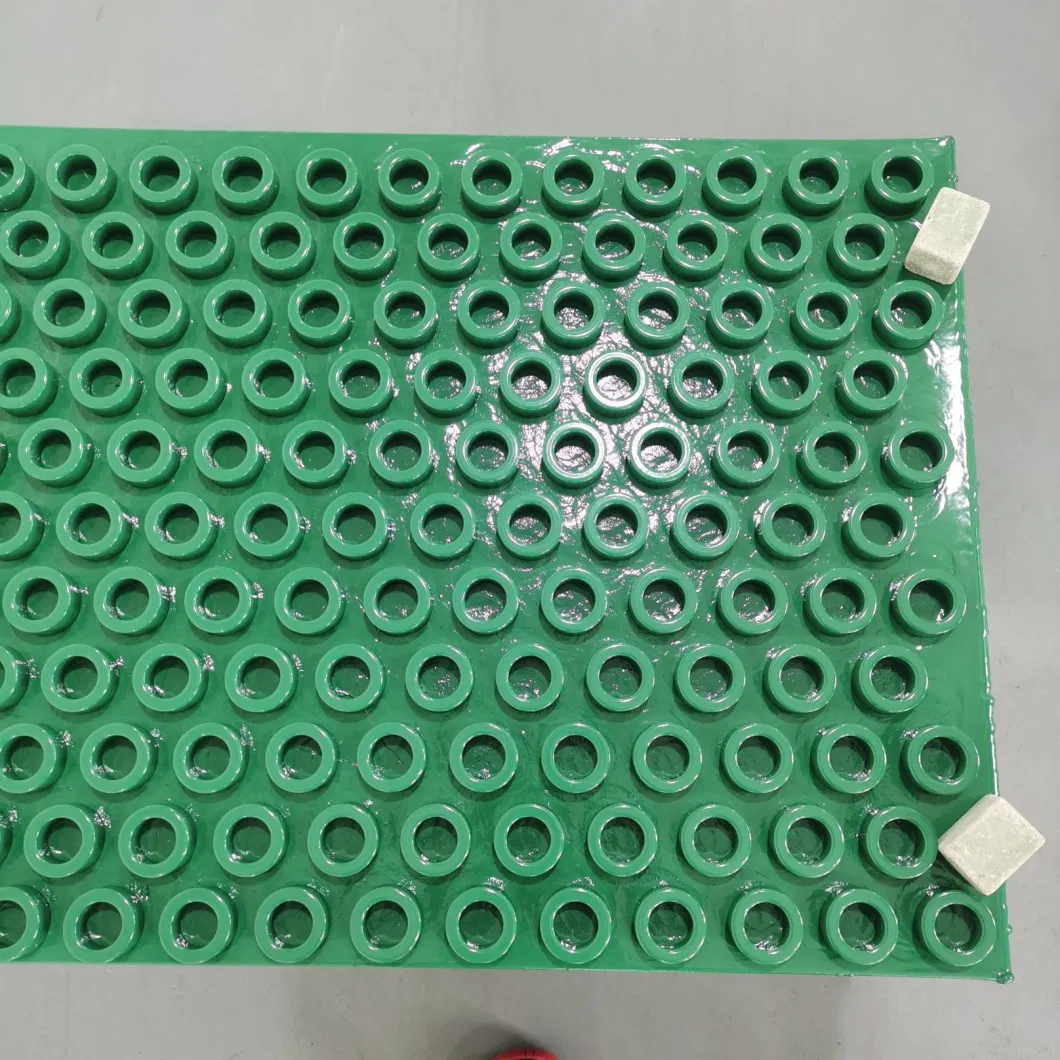

IntroductionThis product is one kind of thermoset pure epoxy powder coating based on epoxy polyester and epoxy curing agent.Electrical insulation can be provided by materials that facilitate the electric isolation of two parts at different voltages. Electrical insulation coatings are also known as dielectric coatings. An epoxy powder coating has insulation properties that make it effective as a high dielectric insulator on copper or aluminum conductors.Our epoxy insulation powder coating E-RD4962-S7 can offer high dielectric strength while creating durable insulation, impervious to most elements, and allows for closer busbar location in a system ideal for single conductors or multiple conductor assemblies that may have numerous forms.Our insulation powder coating has excellent corner coverage, which can prevent the coating film from being broken down by current from the edge and corner, so as to achieve long-term excellent insulation performance.Field of ApplicationThis series of products are mainly used in the field of electrical insulation and can be applied to the coating of electrical components and metal substrates, which has a high demand for insulation, such as aluminum busbars, copper busbars, motor stators, rotors, transformer, magnet wire, switchboards, etc.Basic FeaturesExcellent electrical insulation property.Excellent physical and mechanical property.Good coverage ability of corner.High-density film.Fast curing. The curing reaction speed can also be adjusted flexibly according to customers' demands to meet different spraying requirements.Without weather resistance and can not be directly used outside.Not includes a solvent and other volatile, environmental-friendly.Key Technical Index| Properties | Index | Test standard | Test Result |

| Film Appearance | Smooth, allow slight orange peel | Eyeballing | Smooth, slight orange peel |

| Wear Resistance | 1000g, 1000 cycles | ASTMD4060CS-17 | Loss 25mg |

| Apparent Density | 1.2 ~ 1.8g/cm3 | GB/T 6554-2003 | 1.3 ~ 1.5 g/cm3 |

| Impact Strength (Normality) | ≥ 30Kv/mm | GB/T 6554-2003 | UL certified passed |

| Volume Electric Resistance Rate (Normality) | ≥ 10∧15Ω·cm | GB/T 6554-2003 | 1.5 ~ 3.5*10∧15Ω·cm |

| Water Absorbing Capacity (Boiling 2h) | < 1.5% | GB/T1738 | Pass |

| Insulated Heat-resistance Level | Grade B, ≥130ºC | IEC60085-2007 | Grade B |

| Heat Impact Properties | -20 ~ 100ºC, 5 times no crack | GB/T 6554-2003 | Pass |

| Salt-spray Test | 1000h, bubble at the engraved line ≤ 3mm | GB/T /T1771-2007 | Pass |

| Corner Coverage | ≥ 60% | GB/T 6554-2003 | Pass |

| Inflaming Retarding | V-0 Grade | UL-94 | UL certified passed |

| Comparative Tracking Index(CTI) | Grade 1 | UL746A | UL certified passed |

| High Amp Arc Ignition(HAI) | Grade 0 | UL746A | UL certified passed |

| Hardness | ≥ 2H | GB/T6739-2006 | 2H |

Specifications

| Application Craft | Spraying Method: Electrostatic spraying or fluidized bed dipping. |

| Film Thickness: It is determined according to the actual application of the customer, and the recommended film thickness range is controlled within 200 ~ 500um. | |

| Substrate Preheating Temperature: 190-200ºC/10~25min (adjusted according to the thickness, size and film thickness of the workpiece). | |

| Curing Condition: 200ºC/10-20min (actual temperature of workpiece surface). | |

| Precautions | This product is not recommended for outdoor use. |

| Different spray thickness will affect color, gloss, appearance and physical and chemical properties. | |

| There is a difference between the laboratory sample and the production line coated board, and the customer needs to adjust the spraying parameters to meet the requirements. | |

| Transportation and Storage | Carton packaging, net weight 20 or 25kg. |

| Non-dangerous goods, no special transportation requirements. | |

| Store in a cool, dry place below 25°C. | |

| Shelf Life | 6 months |

Company Profile:Kinte Materials Science and Technology Co., Ltd. is subordinate to China Machinery Industry Corporation (a key state-owned enterprise directly managed by SASAC, ranking 284 among the world's top 500 in 2021). It is a national high-tech enterprise under China National Electric Apparatus Research Institute Co., Ltd. (Stock Code: 688128), a listed enterprise on the SSE STAR MARKET. Focusing on the R & D, production, and sales of environmentally friendly coatings (powder coatings, waterborne industrial coatings) and powder coating resins, the company is committed to improving the global market competitiveness of China's environmentally friendly coating industry. Now it has become the leader and promoter in China's technological development of environmentally friendly coatings as well as polyester resins for powder coatings! We have gained ISO9001 and ISO14000, ISO18001, RoHS, UL certification, and QUALICOAT Certificates. Due to the excellent and stable quality, our products always enjoy a high reputation at home and overseas, and were sold to more than 30 countries.The powder coating branch was founded in 1992, and now there are two factories (the Guangzhou factory and the Wuhan factory) with an annual production capacity of over 25,000 tons. And we have cooperated with many famous clients such as Gree, Pansonic, HITACHI, Mitsubishi, Walmart, HUAWEI, EMERSON, Hisense, Dicastal, BYD, AAG, etc.We unremittingly stick to the business principle of "Quality is the life, adhere to first-class technology, first-class quality, first-class cost, and first-class brand". We would like to provide a complete set of services and solutions for both domestic and abroad customers and would like to go forward to a brilliant future with you together.

Prev: Custom CNC Machining Services OEM Polishing Anodizing

Next: 2021 UV Epoxy Nano Mirror Chrome Metallic Shiny Golden Steel Powder Coating for Iron

Our Contact

Send now