30 Years Manufacture Aluminum/Stainless Steel/ Sheet Metal Stamping/CNC Machining/Welding/Bending Spare Part for Auto Parts/Furniture/Machine

Description

Basic Info.

| Model NO. | stamping |

| Processing Type | Shaping Metal |

| Material | Carbon Steel |

| Mould | Simple Single Process Dies |

| Surface Processing | Spraying |

| Fine Blanking | Double Acting |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Customized | Customized |

| Certification | ISO9001 |

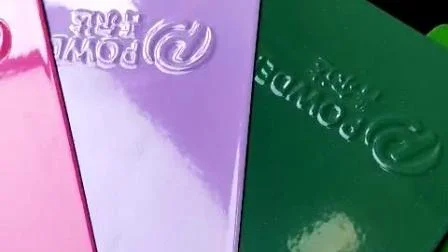

| Surface Treatment | Powder Coating, Black E Coat, Zinc Coat |

| OEM | Accept |

| Welding Fixture Manufacture | in House |

| Thickness | 0.5mm to 15.5 mm |

| Stamping Mould Manufacture | in House |

| Transport Package | Wooded Box |

| Specification | 500mm x 400mm x 6.0mm T |

| Trademark | Sida |

| Origin | Hangzhou |

| HS Code | 7326909000 |

| Production Capacity | 2000000 PCS/Year |

Packaging & Delivery

Package Size 80.00cm * 60.00cm * 50.00cm Package Gross Weight 900.000kgProduct Description

Product DescriptionProduct Description:

30 Years Manufacturer Aluminum / Stainless / Carbon Steel / Sheet Metal Stamping / CNC Machining / Welding / Bending Spare Parts For Automobile / Furniture / Agriculture / Construction / Machine Parts

| Main Business | Stamping, Deep Drawing, Fabrication, Welding, Machining, Tooling, Assembly, etc |

| Product Material | Carbon Steel, Stainless Steel, Aluminum, Alloy steel, Copper, etc |

| Surface Treatment | Powder Coating, Black- E Coat, Zinc / Chrome/ Nickel Plating, Hot Dip Galvanization, Polishing, Silkscreen, Black Oxide. |

| Lead time for tooling and fixture | About 25 days |

| Lead time for a container | About 30 days |

| Tolerance | ASME, ISO-2768 MK |

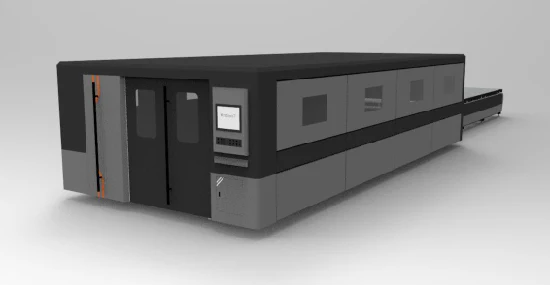

Equipment | Punches:25 sets(Capacity: 6.3ton - 600ton)Deep Drawing Hydraulic Press:2 sets( 100ton-315ton)Welding Robot: 5 sets (FANUC BRAND) Welding Machine: 5 setsLaser Cutting Machine: 2 set Bending Machine: 2 set Machining Equipments: machining center, milling machine, grinding machine, drilling machine, lathe CNC, etc. |

Why Choose Us?

1 · We support ODM and OEM.Based on a real sample or 2-d drawing.

2 · Stamping toolings and welding fixtures are designed and manufactured in house.

3· Metal sheet processing experience since 1994.

4· Stamping and Welding parts export experience since 2004.

5 · Efficient and innovative quality sample service.

6 · Strict quality control system.

7 · Professional online service team, any email or message will be replied within 12 hours.

8 · Products have passed CE, ISO,SPHC,SPCC and other certifications.

9 · Exported to more than 15 countries, including North America, Eastern Europe, Australia, Southeast Asia, Africa, Western Europe, etc.

10 · Customer first, integrity-based.

Production Machines:

Product Display:

Process:

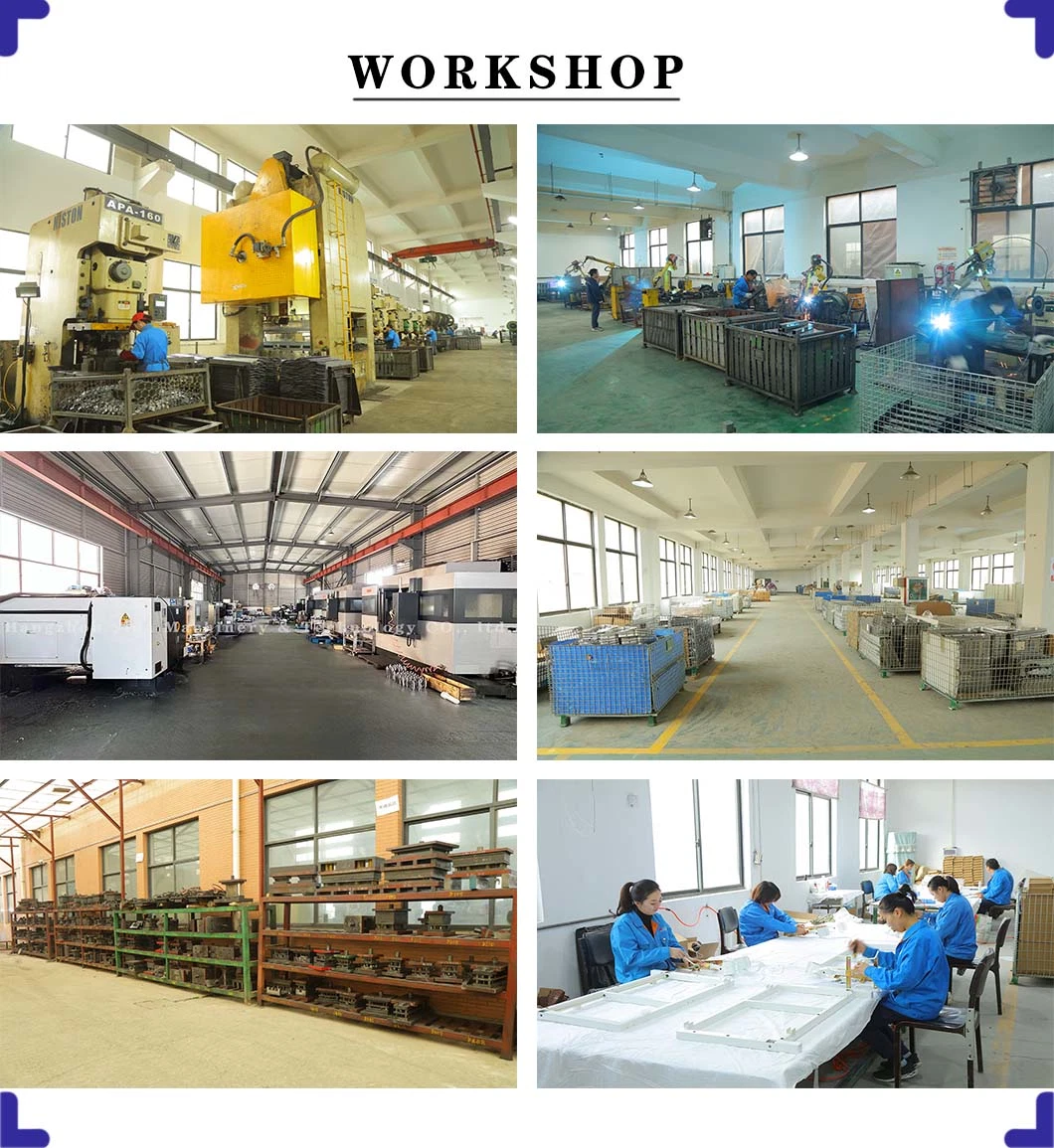

Factory:

HangZhou Sida Machinery & Technology Co.,Ltd. is a professional factory specialized in metal stamping parts and welding parts; 80% of our staffs have more than 15 years experience in metal sheet part industry. All the stamping toolings and welding fixtures are designed and manufactured in house; we can start to work based on your real samples or drawings.Our engineers are willing to provide their best suggestions or solution to ensure stable quality and cost effective production of your parts.

Warehouse and Shipment:

Certifications

Our certificates:

FAQ:

Q1:Where can I get product & price information?

A1:Send us inquiry e-mail or add us whatsapp / skype, we will contact you within 12 hours.

Q2:How long can I get the sample?

A2:Depends on your specific items, within 30 days generally.

Q3:What kinds of information you need for quote?

A3:Kindly please provide the product drawing in PDF, and will be better you can provide 3D drawing in STEP or IGS format, pls let us know your use of part, packing requirements, purchase frequency, and other important infoes, so our offer will be more accurate

Q4: How to guarantee your final size can meet our drawing request?

A4: We will make moulds and fixtures according to your 2D or 3D drawing. Mass production will be released after sample approval; dimensions will be recorded for different batch.

Q5: Generally, how do you packing the goods?

A5: Carton box in wooden pallet or wooden box.

Next: Customized CNC Milling CNC Fabrication Machining Parts Aluminum Housing CNC Machining Machinery Part

Our Contact