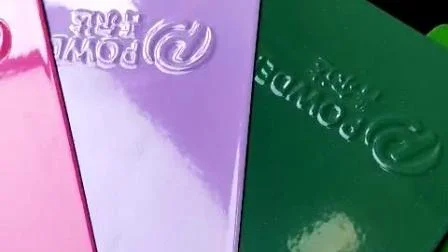

Feihong Brand Electrostatic Spray Epoxy Polyester Ral Color Pintura En Polvo Powder Coating

Description

Basic Info.

| Model NO. | RAL 7032 powder coating powder paint |

| Method | Spray |

| Components | Resin, Pigment, Additive etc... |

| Main Raw Material | Polyester Resin, Epoxy Resin |

| Level | Finish Coat |

| Certification | ISO14001, RoHS, ISO9001 |

| Substrate | Electrostatic Spray |

| Expiration Date | 1 year |

| Formation Mechanism | Electrostatic, Tribo |

| Packaging | 25kgs Carton |

| Factory | We Have Our Own Powder Coating Factory |

| Certificate | ISO, RoHS and SGS |

| Finish | Smooth or Texture |

| Gun | Electrostatic or Tribo Spray |

| Mark | Neutrial or Designed by Customer |

| Annual Export Quantity | 3, 000 Tons |

| Gloss | Glossy, Semi Glossy, Matt |

| Application | Shelf, Fence, Aluminium, Security Door and Others |

| Color on Basis | Ral or Pantone Chart |

| Transport Package | 25kgs Carton |

| Specification | RAL colors or Pantone colors |

| Trademark | EVER |

| Origin | China |

| HS Code | 1111111 |

| Production Capacity | 6000tons/Year |

Product Description

FEIHONG brand Electrostatic Spray/Tribo Matt Epoxy Polyester Ral/Color Powder Coating Powder

Powder Coating for aluminium extrution

Powder Coating for racking system

Powder Coating for electric cabinet

Powder Coating for exterior fence

Powder Coating for metal furniture

- RAL colors powder coating powder paint

- Pantone colors powder coating paint

- Color-matching regarding customer requirement available

GENERAL TYPES

- Polyester / Hybrid powder coating powder paint

- Pure Epoxy Powder coating color/FBE powder coating

- Metallic powder coating color

- Hammer tone powder coating

- Fine Texture color powder coating & powder paint

Textures include sand grain, hammer vein, silk pattern, sand textured, marble,metallic, multi-color.

PHYSICAL PROPERTIES

- Specific gravity :1.2 ~ 1.5g/cm3 on base of defferent colors

- Particle size distribution:100% less than 100 microns (depending on the specific indicators art effects may be, according to the special requirements of painting adjusted)

- Level of liquidity:24 ~ 27 mm

CURING CONDITIONS

180 °C ~ 200 °C (work piece temperature) for 10 to 15 minutesPowder Coating ApplicationPowder Coating for aluminium extrusionPowder Coating for racking systemPowder Coating for cabinetPowder Coating for gas cylinderPowder Coating for exterior fencePowder Coating for metal furniturePowder Coating for iron door

AVERAGE COVERAGE

8-12 square meters per kg, thickness 60-90 microns (100% of the powder coating utilization rate)

PACKING

Outside carton lined with two layers of polyethylene bags, each contain 20kgs or 25kgs N.W.

STORAGE AND TRANSPORT

Stored in less than 30 °C, ventilated, dry, clean room, not near the fire source, heating, avoid direct sunlight, the product in the transport should be to prevent rain, sun, prolonged sun exposure.Storage products in line with the above conditions, since the date of production, effective storage period is 6 months.Over the storage period may be re-tested and the results were consistent with, can still be used.

HEALTH AND SAFETY

Coating powder is a non-toxic products, but should be avoided in the course of inhalation of dust.Proposed operators wear appropriate dust mask, glasses.If possible, try to avoid long-term skin contact with powder coating

Mechanical property | ||

Testing items | Standards and methods | Inspecting index |

Impact strength | GB/T1732-1993, AS3715 2.8 | >50kg/cm |

Bending resistance | GB/T1185-88, AS1580 402.1, ISO9227 | Pass 2-5 millimeters |

Adhesion CHECKED TEST | GB/T9286-88,2mm Cross cut, ISO2409 | Pass100/100, passes 0 levels |

Cupdrawing:Erichsen, ISO1520 | Erichsen, ISO1520 | Pass 3-7 millimeters |

Pencil hardness | GB/T6739-86, Mitsubishi | Pass 1H to 2H |

Chemical resistance and weather resistance | ||

Salt spray test | GB/T1771-91,500 hours | The cross section of corrosion less than 2MM |

Hot and damp resistance test | GB/T17740-79(89),1000 hours | Without air bubbles, loses the light slightly |

Acid resistance | 10% CH3COOH, 240 hours | Without air bubbles, the surface without damage |

Alkali resistance | 10% NaOH, 240 hours | Without air bubbles, the surface without damage |

Heat resistance | 200degree,1 hour | The color change is lower than E=1.5 |

Solvent resistance | MEK24 hours soaked in solvent-free | Without air bubbles, the surface without damage |

Uvioresistant | QUV-313,500 hours | Gloss higher than 80% lower than the Munsell color change level |

Water tolerance of | 2 hours | No bubble, not falling, losing gloss |

We offer free samples to you.

Prev: Outdoor Metal Parts Polyester Powder Coating Manufacturer

Next: Ral Colors Epoxy Polyester Electrostatic Powder Coating Manufacturer

Our Contact